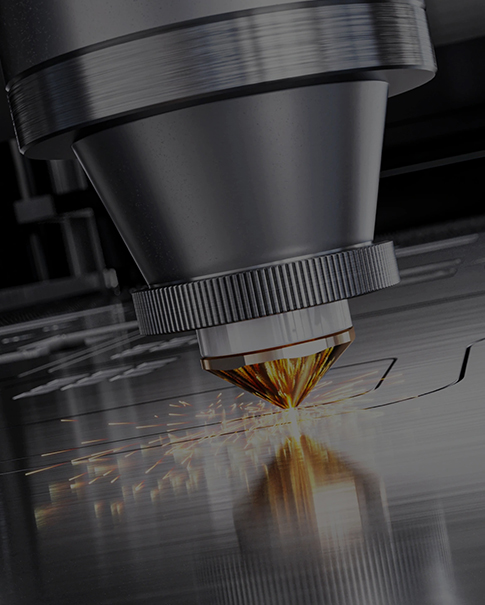

The pelletizer blade is an essential part of the pelletizer. The pelletizer is a molding machine that can produce raw materials into a specific shape. It is widely used in chemical plants, petrochemical industry, pharmaceutical industry, food, decorative building materials, metallurgical industry, environmental protection, printing and dyeing plants, porcelain, plastics, plastics and other industries. According to the structure and principle, it is divided into rotating continuous cold plastic granulator, parallel twin-screw granulator, cylindrical screen drying tableting machine, counter-roller dry granulator (commonly known as counter-roller granulator), counter-tooth granulator Granulator, disc vacuum pump cold granulator, etc.

product name :

Pelletizer blade, hot cutting plastic blade, granulator blade die, hot cutting blade, medicinal granulator bladebrand :

San quShipping Port :

Shanghai/Guangzhou or otherColor :

Natural colorLead Time :

10-15 days after receiving the depositPayment :

T/T,Western unionMaterial :

skd11,cr12mov,h13,9crsi,skd-61,etc.MOQ :

1pcs

| Material: | Tungsten steel alloy,HSS,LD,SKD11,Cr12,Cr12mov,T8,T10,M42,65M,420J.etc. |

| hardness: | HRC46-93 |

| Quench: | Full body heat treatment |

| Surface roughness: | Ra0.2 |

| Thickness tolerance: | ±0.00008" |

| Outer diameter tolerance: | ±0.001″ |

| Parallelism: | ±0.0001″ |

| Standard sizes: | Customized according to drawings |

Our advantage:

Our company specializes in the production of granulator blades and has decades of work experience. We are very familiar with the processing technology of granulators.

The greater the strength of the granulator blade, the better the wear resistance standard, mainly because the cementite produces particles that are uniform at the cutting edge. The strength of vanadium carbide particles is 85HRC, the strength of chromium carbide particles is 72HRC, and the strength of iron carbide particles is 85HRC. The strength analysis of raw material particles can reach 100HRC. The more uniform the distribution of cementite and its particles, the better the wear resistance. Some cementite has the relative density of particles. The higher the density of cementite as particulate matter, the greater the edge retention (wear resistance).

Pelletizer blades are mainly used in metal materials and amorphous strip cutting production lines. They use stable high-speed cutting alloy steel SKD, SKH, tungsten steel and other materials. Through a complete set of heat treatment processing technology, the strength is uniform. Precision machining and production. The pelletizer blade is an important part of the cutterhead, and its processing accuracy is also very high. Pelletizer blades are mainly used for slitting printing paper, tape, audio tapes, plastic films, gold, silver, copper, aluminum, titanium alloy foil and other items.

Our production process :

1.Cutting 2.Forging 3.Plastic surgery 4.Heat treatment 5.Modification 6.Slice

7.Slice 8.Sharpen 9.Plastic surgery 10.fine grinding 11.Plastic surgery

12.Chamfer 13.Test 14.Package 15.Factory

Our products serve all walks of life:Metallurgical industry, plastic industry, food industry, printing industry, electrical appliance industry, rubber industry, woodworking industry, shipbuilding industry, light industry machinery industry, etc.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1:Are you Trading company or Factory?

We are factory,and we have experience for 20 years.

2:Can I have one piece for sample?

Of course yes, nothing can prove our production's quality but sample. You can order one piece on line and our customer service will contact with you as soon as possible.

3: How long is your delivery time?

Generally, it will be within 24 hours after received the payment,Mass production need 20days,Make mould need 15days.

4: What’s kind of trading term can you do?

If you have your usually trading term, please tell our customer service, if not , we can do Ex-works, FOB,CFR,CIF etc .

5: How about the quality of blades ?

Our blades adopt advanced technology. Moreover, we carry out strict supervision during productionand make sure every finishedproduct with high quality.

Tags :