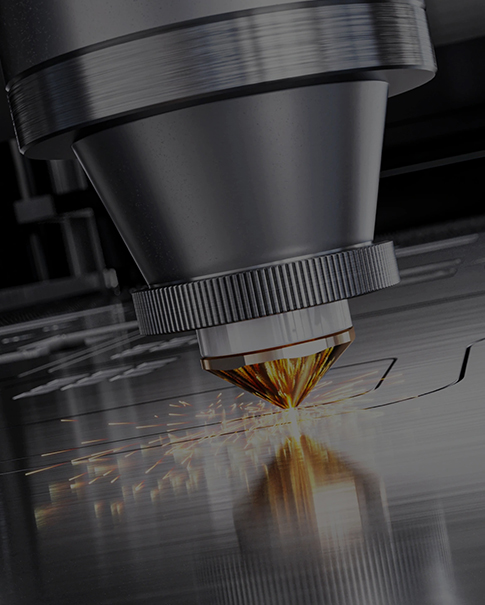

Whether it is war in history or cutting and processing in modern industry, blades are vital tools. As the core component of blades, the type of metal plays a vital role in the quality, durability and performance of blades. So, which metal is best for making blades? This question seems simple, but there is a lot of deep knowledge and technology behind it.

1. Iron, steel, alloy: common metals for making blades

Historically, the first metal used by people was iron. Iron is a common metal that is easy to process and modulate, so it became the main material for sword manufacturing in ancient times. With the advancement of technology, the emergence of steel has greatly improved the quality and performance of blades. Steel is an alloy of carbon (C) and iron (Fe). By controlling the carbon content and adding other alloying elements, blades for various purposes can be made. In industrial and military applications, various alloys are also widely used to make high-performance blades, such as titanium alloys, tungsten alloys, etc.

2. Characteristics of different metals

Different metals have their own unique properties and are suitable for different blade applications. Here is a brief introduction to several common metals:

Stainless Steel: Stainless steel has good corrosion resistance and mechanical properties, so it is widely used in kitchen knives and blades in daily life.

Carbon Steel: Carbon steel has high hardness, is easy to sharpen, and has good cutting performance, but it is easily oxidized by moisture.

D2 Tool Steel: D2 Tool Steel has excellent cutting performance and wear resistance and is widely used in industrial and military fields.

VG10 Stainless Steel: VG10 Stainless Steel is a high-quality stainless steel that is often used in the manufacture of high-end kitchen knives.

Titanium Alloy: Titanium Alloy has excellent corrosion resistance and lightweight properties and is widely used in outdoor knives and aerospace fields.

3. How to choose the right metal

Choosing the right metal depends on the purpose and needs of the blade. When choosing a metal, you need to consider the following factors:

Hardness and wear resistance: The blade needs to have sufficient hardness and wear resistance to ensure that it remains sharp during use.

Corrosion resistance: In some environments, blades are susceptible to corrosion, so it is very important to choose metals with good corrosion resistance.

Blade break resistance: Blades are subject to various impacts and pressures during use, so the blade material needs to have a certain toughness and break resistance.

Price and manufacturing process: Different metals have different prices and manufacturing difficulties. When choosing metals, you need to consider production costs and processing technology.

Whether it is traditional manual manufacturing or modern industrial production, choosing the right metal material is crucial to making high-quality blades. Only by understanding the characteristics of various metals and selecting the best metal material according to the specific needs of the blade can you make a durable, sharp blade suitable for a specific scenario.