The shredder blade is an important accessory of the shredder. The quality of the shredder blade directly affects the machine's processing cycle of waste materials. According to the classification of the shredder, the shredder blade is divided into single-shaft shredder blade and Multi-shaft shredder blades. As an important crushing knife on the shredder. According to the shredder structure classification, shredder blades can be divided into single-shaft shredder blades and multi-shaft shredder blades (including dual-shaft shredder blades and four-shaft shredder blades).

product name :

Double shaft shredder bladebrand :

San quShipping Port :

Shanghai/Guangzhou or otherColor :

Natural color/silver/black/golden yellow or otherLead Time :

15-20 days after receiving the depositPayment :

T/T,Western unionMaterial :

H13/H13K/LD/SKD11/HMB/H13+W/HSS,etcMOQ :

1pcs

| Application machinery | Shredder machine |

| Application | Suitable for shredding paint buckets, scrap steel, wood, scrap furniture, rubber, fiber, paper, etc. |

| Size | We can customize according to your requirements |

| Material | H13/H13K/LD/SKD11/HMB/H13+W/HSS,etc |

| Hardness | HRC46-93 |

| MOQ | 1PCS |

| Thickness tolerance: | ±0.00008" |

| Surface roughness: | Ra0.2 |

| Outer diameter tolerance: | ±0.001″ |

| Parallelism: | ±0.0001″ |

| Package: |

1.Apply anti-rust oil 2.Packed in plywood wooden box 3.Increase moisture-proof and anti-smashing measures |

Product display:

| General size | |||

| Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness | Outer diameter*inner diameter*thickness |

| Φ76.2×Φ17×2.2/5 | Φ76.2×Φ17×3/5 | Φ76.2×Φ19×2.2/6 | Φ76.2×Φ19×3/6 |

| Φ76.2×Φ22×3/6 | Φ220×Φ100/110×20 | Φ260×Φ110/120×20 | Φ280×Φ120/125×20 |

| Φ300×Φ140/150×25 | Φ300×Φ140/150×30 | Φ350×Φ150/160×40 | Φ400×Φ170/180×40 |

| Φ450×Φ190/200×50 | Φ500×Φ220/230×50 | ||

The multi-axis shredder blade is a claw knife, which is installed on a dual-shaft or four-shaft shredder according to the design of each company. It can generally be divided into 3-claw shredder blades, 8-claw shredder blades, and 12-claw shredders. Blades, etc., are used for crushing, shredding and extruding to reduce the size of materials. This shredder blade is used for crushing waste plastics, waste rubber, wood and other large-volume wastes.

The shredder blades are generally made of 55SiCr and H13K, which are suitable for shredding paint buckets, scrap steel, wood, scrap furniture, high-hardness plastics, etc. Cr12MoV and SKD-11 are cold work die steels. The properties of these two materials are similar. The tools made of this material have high hardness but are relatively brittle. They are suitable for soft waste materials such as rubber, fiber, and paper.

Commonly used shredder cutter specifications range from 200mm to 700mm in diameter and 20mm to 100mm in thickness. Most of the inner holes are hexagonal. They can also be made into octagonal or circular (with keyway) according to customer needs. The shredder blade adopts salt bath furnace quenching and vacuum furnace quenching, which can make the hardness of cutting tools of various materials and specifications meet the requirements.

Our advantage:

1. High-quality materials: Ma'anshan Sanqu Machinery Technology Co., Ltd. uses high-quality imported materials to manufacture blades to ensure the product's sturdiness and durability. These materials have excellent anti-aging, anti-oxidation, wear-resistant and anti-pollution capabilities, so the products are very reliable during use.

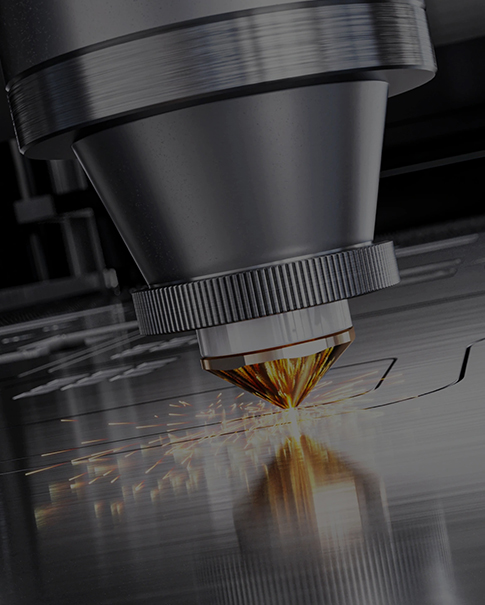

2. Advanced CNC technology: The company uses advanced CNC technology for blade processing to ensure that the blade size is accurate, with minimal dimensional deviation and no burrs. This ensures that the inserts meet customer requirements and are able to meet the high precision demands of tool use.

3. Advanced grinder: Ma'anshan Sanqu Machinery Technology Co., Ltd. uses an advanced grinder to process the blades. This is a double insurance measure that can ensure the quality and accuracy of the blades. This processing process eliminates customers' worries and ensures the stability and reliability of blade performance.

4. Professional thermal processing: The company has professional thermal processing equipment and experienced staff. Through exquisite thermal processing technology, the performance of the blades produced by Ma'anshan Sanqu Machinery Technology Co., Ltd. is higher than that of blades produced by general manufacturers on the market, and can meet the higher requirements of customers.

5. Strict inspection requirements: Maanshan Sanqu Machinery Technology Co., Ltd. conducts strict inspections on blades to ensure that every product delivered to customers is of high quality. This strict inspection process ensures the reliability and stability of the product, allowing customers to use the blades with confidence.

Our production process :

1.Cutting 2.Forging 3.Plastic surgery 4.Heat treatment 5.Modification 6.Slice

7.Slice 8.Sharpen 9.Plastic surgery 10.fine grinding 11.Plastic surgery

12.Chamfer 13.Test 14.Package 15.Factory

Our products serve all walks of life:Metallurgical industry, plastic industry, food industry, printing industry, electrical appliance industry, rubber industry, woodworking industry, shipbuilding industry, light industry machinery industry, etc.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1:Are you Trading company or Factory?

We are factory,and we have experience for 20 years.

2:Can I have one piece for sample?

Of course yes, nothing can prove our production's quality but sample. You can order one piece on line and our customer service will contact with you as soon as possible.

3: How long is your delivery time?

Generally, it will be within 24 hours after received the payment,Mass production need 20days,Make mould need 15days.

4: What’s kind of trading term can you do?

If you have your usually trading term, please tell our customer service, if not , we can do Ex-works, FOB,CFR,CIF etc .

5: How about the quality of blades ?

Our blades adopt advanced technology. Moreover, we carry out strict supervision during productionand make sure every finishedproduct with high quality.

Tags :