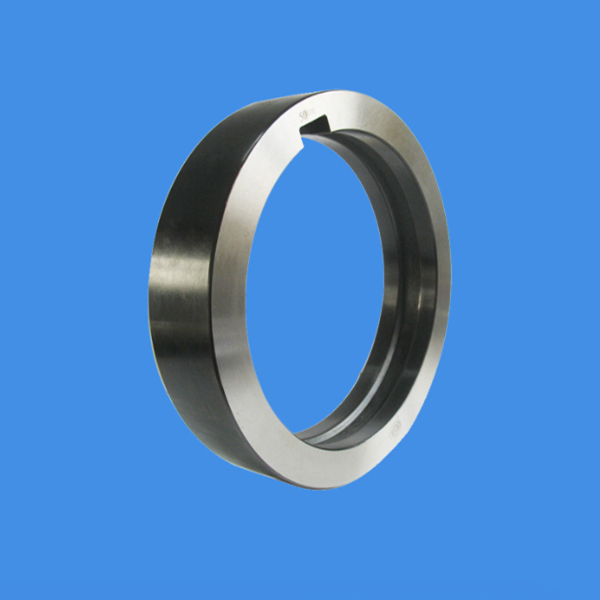

The slitting machine separation disc (guide disc) is used on the slitting machine shaft to separate and guide the slitting of narrow materials to facilitate rewinding the materials into narrow rolls.

product name :

Industrial round metal gasketbrand :

San quShipping Port :

Shanghai/Guangzhou or otherColor :

Natural color/silver/black/golden yellow or otherLead Time :

15-20 days after receiving the depositPayment :

T/T,Western unionMaterial :

skd11,cr12mov,h13,9crsi,skd-61,etc.MOQ :

1pcs| Application machinery | Rolling shear machine |

| Application | The winThe slitting machine separation disc (guide disc) is used on the slitting machine shaft to separate and guide narrow materials. |

| Size | We can customize according to your requirements |

| Material | skd11,cr12mov,h13,9crsi,skd-61,etc. |

| Hardness | HRC46-93 |

| MOQ | 1PCS |

| Thickness tolerance: | ±0.00008" |

| Surface roughness: | Ra0.2 |

| Outer diameter tolerance: | ±0.001″ |

| Parallelism: | ±0.0001″ |

| Package: |

1.Apply anti-rust oil 2.Packed in plywood wooden box 3.Increase moisture-proof and anti-smashing measures |

Purpose: An important part of the sheet metal cutting device. It is used for sheet metal parts. It is suitable for large steel plants, steel pipes, non-ferrous metal processing plants, bundling plants, cold rolling plants, packaging materials plants, steel plate processing service centers, steel Net factory, steel factory, slot machine manufacturer, etc.

Our advantage:

1. High-quality materials: We use high-quality materials to manufacture our blades, such as high-quality carbon steel, high-speed steel, or carbide. These materials offer excellent wear resistance, hardness, and durability to maintain blade sharpness and performance over time during use.

2. Innovative design: We continuously carry out innovative designs to improve the cutting efficiency and accuracy of the cutting tools. We pay attention to the needs of our customers and design suitable blade shapes, blade surface coatings and edge geometries according to different application scenarios. These innovative designs enable our cutting tools to provide higher efficiency and better cutting quality during the machining process.

3. Advanced manufacturing process: We use advanced manufacturing processes and equipment to ensure that each blade has consistent quality and precision. We strictly control various parameters during the production process, including material selection, heat treatment and precision grinding, to ensure the stability and performance of the blades.

4. Diversified product line: We provide a wide range of tool product lines, covering a variety of different types and specifications of blades. Whether the application is milling, turning, drilling or cutting, we have the right tooling solution. Whether you are machining precision parts or producing high volumes, we can meet your needs.

5. Customer service and support: We value our customers' needs and provide excellent customer service and support. Our team will actively communicate with customers to understand their specific needs and application scenarios, and provide them with professional tool selection suggestions and technical support. We are committed to establishing long-term cooperative relationships with our customers and achieving a win-win situation together.

Our production process :

1.Cutting 2.Forging 3.Plastic surgery 4.Heat treatment 5.Modification 6.Slice

7.Slice 8.Sharpen 9.Plastic surgery 10.fine grinding 11.Plastic surgery

12.Chamfer 13.Test 14.Package 15.Factory

Our products serve all walks of life:Metallurgical industry, plastic industry, food industry, printing industry, electrical appliance industry, rubber industry, woodworking industry, shipbuilding industry, light industry machinery industry, etc.

Packing&Shipping

Efficient logistics and distribution: We use fast and reliable logistics partners to ensure that your order can be delivered in time. We work with world-renowned logistics companies to provide flexible logistics options and full tracking services so that you can always know the shipping status of your goods.

FAQ:

1:Are you Trading company or Factory?

We are factory,and we have experience for 20 years.

2:Can I have one piece for sample?

Of course yes, nothing can prove our production's quality but sample. You can order one piece on line and our customer service will contact with you as soon as possible.

3: How long is your delivery time?

Generally, it will be within 24 hours after received the payment,Mass production need 20days,Make mould need 15days.

4: What is a guide plate?

A guide blade is a device used to guide, control or limit the movement or rotation of an object. .

5: The role of the guide plate?

The guide plate can guide the positioning, reduce friction and prevent deformation.

Tags :